Concrete Pressure Pipe

Case Study: PCCP The Pipe Of Choice In Difficult Conditions

Year after year one major metropolitan city continues to purchase PCCP (AWWA C301). Read this case study on prestressed concrete cylinder pipe and learn why it is the go-to pipe for area plagued with soggy conditions and corrosive soil.

Continue Reading

Case Study: PCCP For Power Generation

Read this case study and learn why prestressed concrete cylinder pipe is the choice for the power generation market.

Continue Reading

Case Study: 63-Mile Bar-Wrapped Pipeline

Concrete pressure pipe combines the tensile strength of steel with the compressive strength and corrosion-inhibiting properties of Portland cement concrete and mortar. The stiffest and strongest of the commonly specified semirigid water pipes, C303 bar-wrapped pipe is manufactured using a welded steel cylinder with sized, welded-steel joint rings attached. The steel cylinder is lined with […]

Continue Reading

Case Study: Trenchless PCCP

PROJECT OVERVIEW As part of the Milwaukee Metropolitan Sewerage District’s Overflow Reduction Plan, the city embarked on the Harbor Siphons project that expanded the capacity of the district’s interceptor system to deliver sewage flows equal to the capacity of the North Wastewater Treatment Plant. This project serves to transfer wastewater that is diverted to the […]

Continue Reading

Case Study: Contractors Share Details On Bar-Wrapped Pipe Installation

In 2017 the demand for water in Corpus Christi, Texas, was more than 34 billion gallons of water. Industrial growth accounted for nearly 50 percent of water use, but in 2025 that number is expected to rise to 70 percent. Thompson Pipe Group manufactured 93,950 linear feet of 48” bar-wrapped pipe (AWWA C303) for the […]

Continue Reading

Case Study:Today’s PCCP Sparks New Life Under Power Lines

OVERVIEW Erie County is home to nearly 1 million people in western New York.The Buffalo-Niagra metropolitan area is the second largest region in the state. In the 1970s, 30” prestressed concrete cylinder pipe (PCCP) manufactured by Interpace was installed near an electric grid system. During this time Interpace PCCP included defective materials and poor practices. […]

Continue Reading

84″ PCCP Powers New Natural Gas Facility

When Florida Power and Light put into service the Dania Beach power facility Calvin Coolidge was president. In 2018, 91 years after it began operations, the service provider began dismantling the location to make way for one of the cleanest most efficient power plants of its kind. Located between Fort Lauderdale and Miami, the new […]

Continue Reading

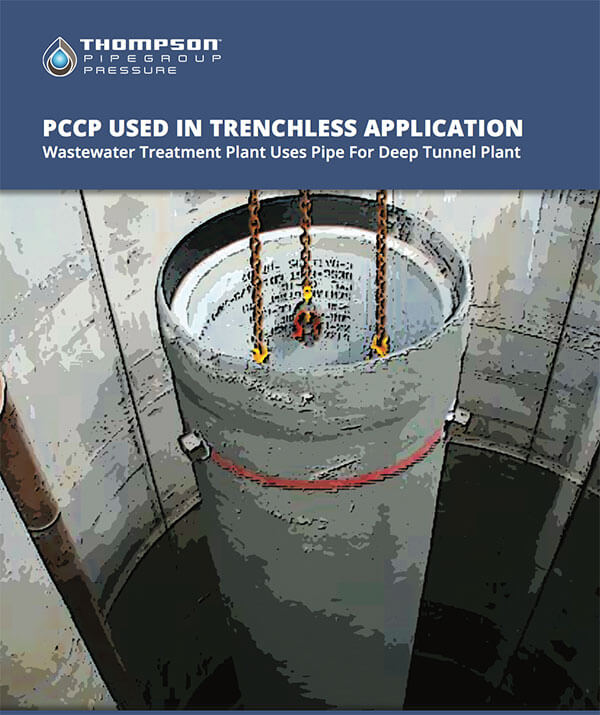

Case Study: PCCP For Trenchless Applications

Project Overview As one of the largest metropolitan areas in the country, downtown Dallas is home to big buildings, mass transit, and bustling streets. To avoid road closures, costly traffic maintenance and utility conflicts, engineers chose a trenchless installation of 1,800 linear feet of 36” prestressed concrete cylinder pipe. Arredondo, Zepeda & Brunz Project Manager Steve […]

Continue Reading

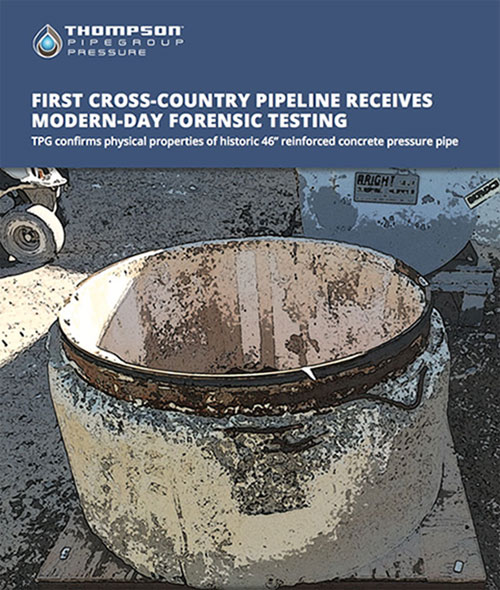

Case Study: First Cross-Country Pipe Receives Modern Day Testing

Project Overview In the mid-1930s city engineers in Grand Rapids, Michigan, determined Lake Michigan water would be easier to transport and treat than their current source, the Grand River. Engineering consultants proposed welded steel or cast iron pipe for the 31-mile, 46-inch- diameter pressure pipeline. However, the city allowed Price Brothers Company, a Thompson Pipe Group […]

Continue Reading

Tunnel Business Magazine Features TPG Pipe

The Atoka Pipeline is the largest water pipeline under construction in North America. Read this story in Tunnel Business Magazine and learn how Thompson Pipe Group is manufacturing large diameter reinforced concrete microtunneling pipe.

Continue Reading

Case Study: Largest Water P3 In North America

Thompson Pipe Group manufactured and delivered bar-wrapped and steel pipe for the largest public-private partnership in North America. Read this case study and learn more about why these materials were selected by the San Antonio Water System.

Continue ReadingFRP

Case Study: Flowtite FRP Offers Huge Savings

Selecting Flowtite® FRP reduced annual operating and maintenance costs by 25% as compared with PVC and 50% as compared with HDPE. Plus, the pipe withstood harsh winter weather. The contractor was able to install 1,500 LF per day. Read more about the Port of Morrow Regional Water Recycle and Re-Use Project in Oregon.

Continue Reading

Fiberglass Pipe With Steel Fittings

Thompson Pipe Group engineers value engineered this project to accelerate installation and reduce costs. Read how we designed and manufactured steel fittings for 72” and 75” fiberglass pipe.

Continue Reading

Case Study: Microtunneling With Flowtite® FRPM Jacking Pipe

Learn how Flowtite® FRPM Jacking Pipe helped save money and accelerate installation.

Continue Reading

Case Study: FRP Joint Options

In 2017 approximately 3,500 linear feet of 30” Flowtite® fiberglass reinforced polymer (FRP) pipe with a pressure class of 300 psi was installed in Henderson, Nevada. Due to corrosive soil the Galleria Reclaimed Waterline required numerous corrosion related repairs. The geotechnical evaluation indicated the soils are too corrosive for buried steel and required a non-corrosive […]

Continue Reading

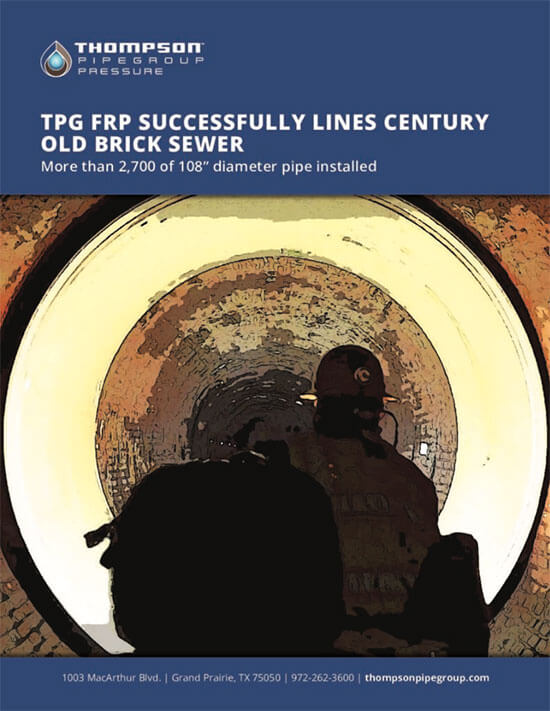

Case Study: TPG FRP Lines Brick Sewer

Why Trenchless Taggart Outfall is a 114-year-old sewer in southeast Portland. Originally dug by hand in an undeveloped area, today it runs beneath homes, businesses, a highway and active rail lines. Digging an open trench would require ripping out existing infrastructure and demolishing buildings. Value Engineering With no shaft location identified, the initial trenchless design […]

Continue ReadingPipeline Services

Case Study: Historical Records Available

We don’t guess. We know. Our Pipeline Services Group has access to historical records for approximately 80% of the country’s large diameter concrete pressure pipe installation records. Read this case study and learn how the City of Charlotte, North Carolina, benefitted from our services.

Continue ReadingSteel

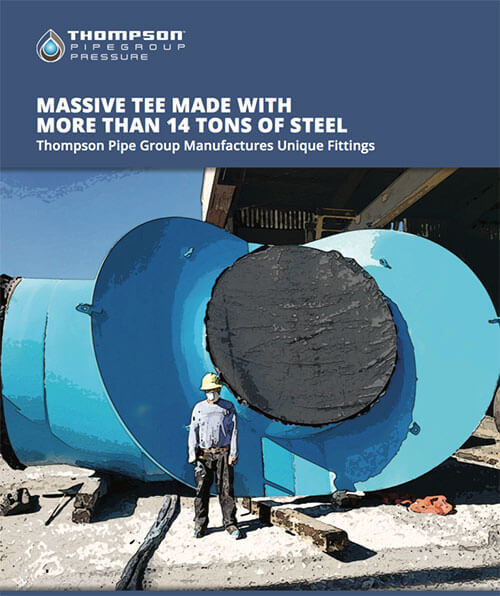

Case Study: Massive Fitting Made With 14 Tons Of Steel

As a complement to pipe, Thompson Pipe Group manufactures all required projectttings. This 120” x 96” with a 120” x 108” eccentric reducer was produced for the City of Houston. Learn more in the case study below.

Continue ReadingMisc.

Case Study: Sliplining Water Main Saves Money And Time

Every drop of water is precious in the Sonoran Desert. The City of Phoenix saved time and money by selecting sliplining as the repair option. Thompson Pipe Group manufactured and delivered approximately 1-mile of 56-inch steel liner pipe and gave the existing 60” watermain renewed life. Read this case study to learn more.

Continue Reading

Case Study: Snap Ring Offers Installation Benefits

A Snap Ring® is a mechanically restrained joint system with several benefits. Read this case study and learn more:

Continue Reading

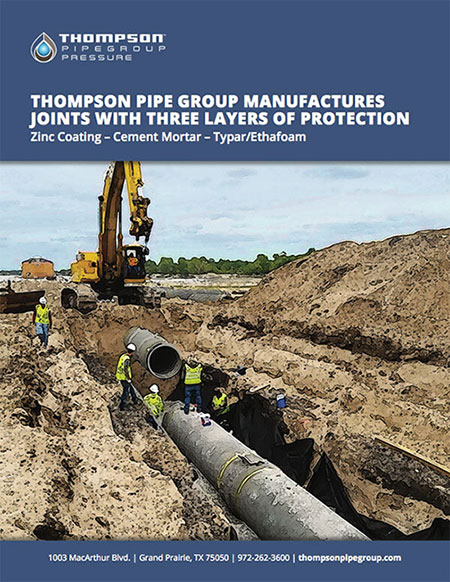

Case Study: Three Layers Of Joint Protection

Read this case study and learn how Thompson Pipe Group protects steel components in concrete pressure pipe joints with three layers of exterior protection: zinc metallized coating, cement mortar and Typar/Ethafoam.

Continue Reading