Why Trenchless

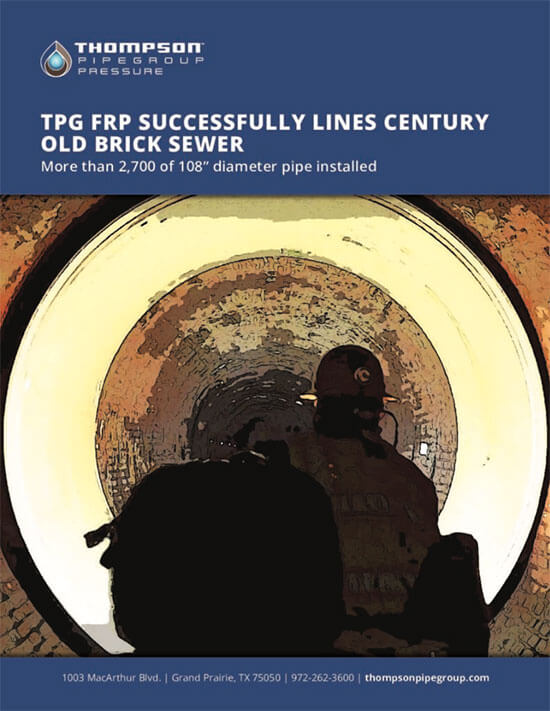

Taggart Outfall is a 114-year-old sewer in southeast Portland. Originally dug by hand in an undeveloped area, today it runs beneath homes, businesses, a highway and active rail lines. Digging an open trench would require ripping out existing infrastructure and demolishing buildings.

Value Engineering

With no shaft location identified, the initial trenchless design included tunnel liner plates. After the project was awarded to contractor James W. Fowler, company engineers found an empty parking lot above the Taggart Outfall. They proposed the location for a shaft and recommended lining the old brick sewer with fiberglass pipe. Project manager Phiet Vuong said installing sections of berglass pipe moved faster than the initial proposed solution,“Tunnel liner plates are bolted together piece by piece inside the tunnel,” he said. “Carrying in whole sections of FRP made the installation faster.”

Engineers used 3D scans of the sewer line to design Thompson Pipe Fiberglass Reinforced Pipe. More than 2,700’ of TPG FRP was manufactured in Colombia and shipped to Oregon. Due to the precise design and manufacturing, some sections had less than an inch of clearance. The thin-walled pipe is durable. The smooth interior surface with a Mannings coefficient of 0.009 is much smoother than the host pipe which means the reduction in capacity is minimized. In some cases relining with FRP may increase capacity. Additionally, flush joints minimized pipe diameter reduction by reducing the amount of annular spaces needed to install the pipe. John Elliot with James W. Fowler served as project superintendent and noted the tight fit of the flush joint pipe in the relining operation,“There were curved sections with less than an inch of clearance between the FRP and the host pipe.”

Additional Benefits of TPG FRP

-

- Corrosion resistant

- Low operating maintenance

- Ease of installation

- Custom joint lengths

- Custom ID/ODs

- Installed in live flow or carried into place

- Low cost of transportation, lightweight pipes can be nested

- No concerns with heat of hydration with annular space grouting

- 100+ year design life