PROJECT OVERVIEW

As part of the Milwaukee Metropolitan Sewerage District’s Overflow Reduction Plan, the city embarked on the Harbor Siphons project that expanded the capacity of the district’s interceptor system to deliver sewage flows equal to the capacity of the North Wastewater Treatment Plant. This project serves to transfer wastewater that is diverted to the Deep Tunnel System, directly to the treatment plant, and it reduces sewer overflows and residential backups while allowing for cleaning and rehabilitation of the original siphon.

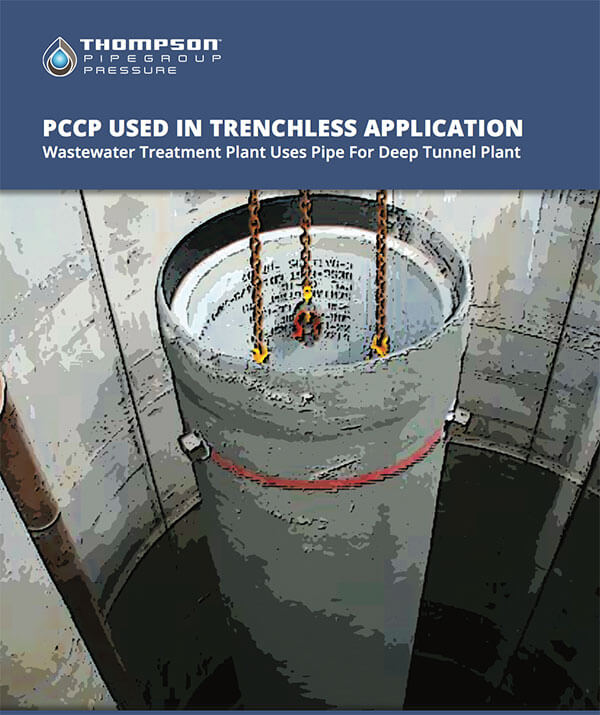

To reach the plant, crews had to install vertical shafts 300 feet deep into the river, tunnel under the river and under the island, and then back up into the plant. The shafts and tunnels hold L-301 and E-301 concrete pressure pipe in seven diameters ranging from 42 inches to 96 inches. The project required multiple types of pipe, large quantities of custom designed fittings, mechanically restrained testable joints, and specially designed lifting lugs.

Installing the pipes down into the vertical shafts required tremendous coordination and pre planning; dual rubber O-ring testable joints allowed each joint to be air tested upon installation, an essential feature since the pipes were inaccessible once the process was completed. Along with the testable joints, PCCP was an ideal material for this application because of its ability to withstand the rigors of the installation and the resulting tunnel loads.