Thompson Pipe Group

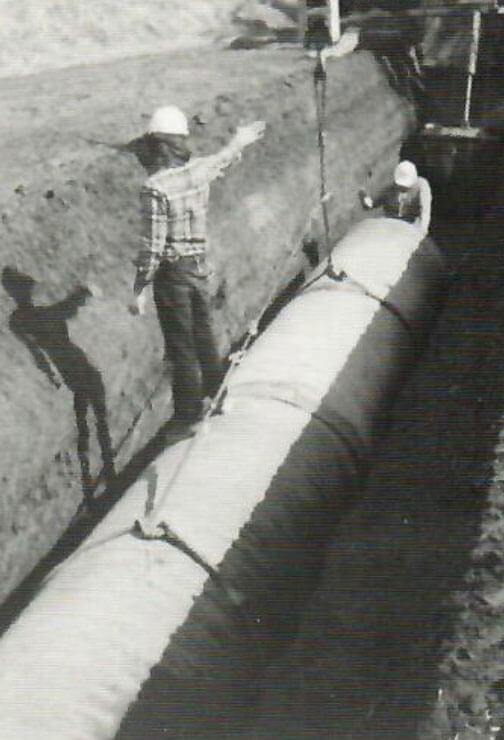

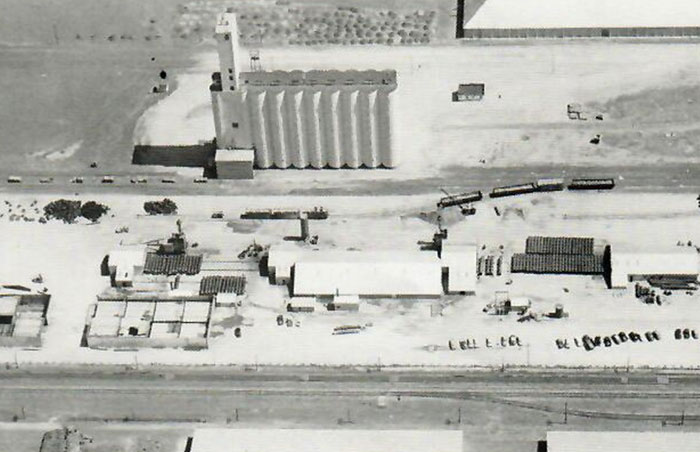

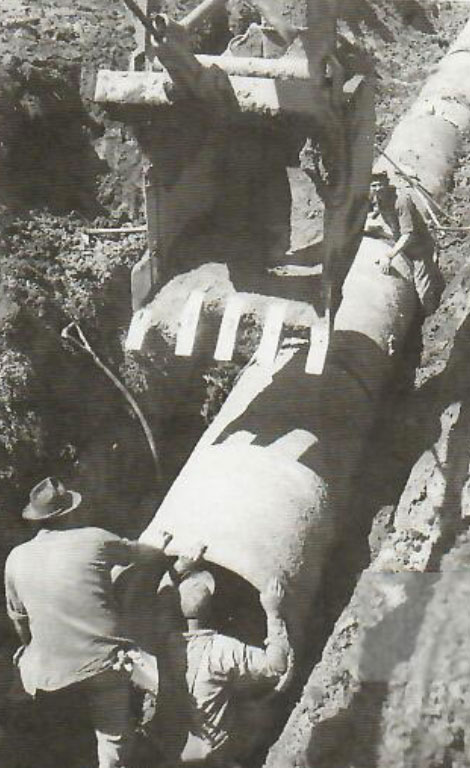

We’re a privately held family business of engineers, contractors and manufacturers based in Rialto, California. From our humble beginnings, we built a family of products to meet the needs of all kinds of infrastructure. Each generation of products is better than the previous. Thompson Pipe Group (TPG) is now the largest and most diverse drainage, sanitary, pressure and trenchless pipe provider, with manufacturing locations across the country and serving not just the US but all of North America.

We’ve got this.

Our nation’s underground infrastructure is in dire need of rehabilitation and, in many places, replacement. It’s an enormous challenge, but one that TPG is poised to meet head-on with our complete range of pipe products and our collaborative engineering support resources behind them.

Bring it on.

TPG has never been more ready. We’ve evolved to tackle the biggest, most complex challenges on a continental scale. Exactly the right product for the right application. Our legacy is focused on making the world a better place for the next generation and those to come.

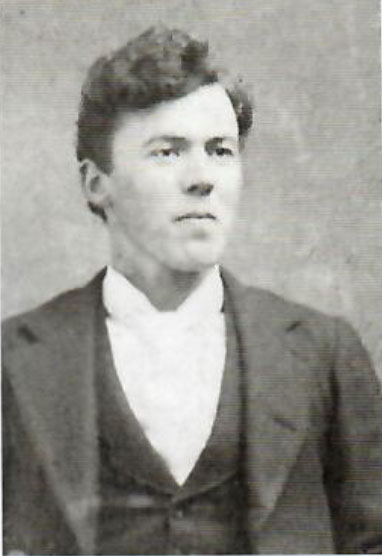

“Because of our roots as contractors, we know what’s needed to be the best partners to water owners, engineers and contractors.”

— CEO, Ken D. ThompsonMade with true grit.

You won’t find a company more passionate about this industry than TPG. We’re zealously committed to being collaborative partners. Besides being engineers and contractors ourselves, we operate from the utmost of ethics. We’re big believers in character-driven leadership and practical innovation. Most of all, we believe that good, old-fashioned American grit is the blueprint to success.

A place with a heart and soul.

At TPG, we believe in giving back. We provide a work environment where our employees can build a life. We don’t just offer jobs, we offer careers. And we’re committed to always doing the right thing for our industry, our people and our community.

Locations